As is well known, there is a wide range of sensors available on the market. Capacitive sensors are industrial sensors used to determine the position of conductive and non-conductive materials, without distinguishing between materials, and are less affected by environmental conditions. They are used to measure the distance of materials. Capacitive sensors detect changes in capacitance caused by variations in the electric field. They can detect the presence or absence of nearly any object, making them widely used in industrial automation.

Applications of Capacitive Sensors

Capacitive sensors are utilized in various applications, including position detection, position measurement, thickness measurement, dynamic movement, liquid level detection, touch detection, precision measurement, personnel detection, and moist environments. In industrial settings, capacitive sensors are employed in humid areas and are often perceived as humidity sensors. They offer relatively high linearity between 20% and 80% relative humidity. Because they can precisely detect temperature and humidity parameters, they also contribute to the operation of air purification equipment.

Capacitive sensors measure thickness, level, and pressure with reliable accuracy. These level measurements ensure the continuous availability of materials. Capacitive sensors can be used for liquid level detection applications.

How Capacitive Sensors Work

Capacitive sensors operate on a specific principle. These sensors activate their capacitance property to perform measurement functions. When a voltage is applied between two conductors separated by an insulator, opposite charges accumulate on the surfaces of these conductors, creating an electric field. This electric field is referred to as capacitance.

Products entering this field alter the magnetic position due to their presence. At this stage, the capacitive sensor uses its detection function to generate an output signal.

The area of interest is inversely proportional to the distance between the plates. Products that are closer together or larger cause a larger current. Consequently, a capacitive sensor can adjust the distance detection level based on the size or type of material. For example, it can detect iron at 1.0 cm and glass at 0.6 cm.

Information About Capacitive Sensor Connection Cables

For the reliable operation and continuity of the system, capacitive sensors use a 24 VDC power supply technique. According to this technique, capacitive sensors have three connection cables: two for power supply and one for the signal. The signal cable is black, while the power supply cables are blue and brown. The signal cable transmits output after the capacitive sensor detects the material.

It is important to determine the appropriate end of the material for power supply after the output stage. If the material is supplied with positive voltage, a PNP-type sensor should be chosen.

Features of Capacitive Sensors

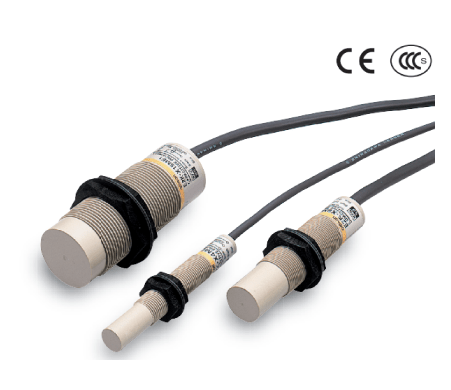

Capacitive sensors have characteristics related to their structure, dimensions, and detection ranges. The detection range of capacitive sensors varies based on their construction, generally between 8 and 40 mm. Their structure can be cylindrical or cubic, with dimensions determined by their design. For example, cylindrical capacitive sensors come in sizes like M18, M30, and M12, while cubic sensors are produced in various sizes to meet different needs.

Types of Capacitive Sensors

Capacitive sensors are classified based on their size, structure, and detection range. They are also categorized according to their mounting types: flush mounting, semi-flush mounting, and protruding mounting. Electrical connection styles include wired, wired with socket, and socket-only connections. Socketed sensors typically have M12 or M8 threads, and connection types include 2-wire or 3-wire configurations.

Capacitive sensors can have NPN, PNP, or both NPN and PNP outputs. They are also categorized by their output function into NO (normally open) and NC (normally closed) types.

Applications of Capacitive Sensors

Capacitive sensors have a broad range of applications in industry. Major applications include:

- Flow measurement

- Pressure measurement

- Void measurement

- Thickness measurement

- Liquid level measurement