Timers

Timers are essential components in industrial automation, playing a crucial role in controlling processes that require precise timing. These devices allow equipment to operate for a specified duration or delay actions until certain conditions are met, ensuring that processes run smoothly and efficiently. In industries like manufacturing, energy, and logistics, timers are used for applications such as machine sequencing, delaying motor start-up, and regulating production cycles. For companies selling industrial sensors, offering high-quality timers is key to providing customers with comprehensive automation solutions.

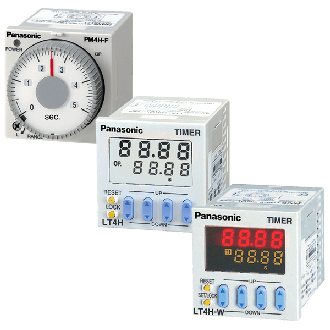

Industrial timers come in various forms, including analog, digital, and programmable models, each suited for different applications. These timers can be used in conjunction with industrial sensors and control systems to manage tasks like delayed start-ups, cycle timing, or even safety operations, such as ensuring a machine remains inactive until safety conditions are confirmed. By precisely controlling time intervals, timers help improve productivity and prevent errors in automated processes.

One of the main benefits of industrial timers is their reliability. Built to withstand harsh industrial conditions, such as extreme temperatures, humidity, and vibrations, timers are designed for long-term, trouble-free operation. Additionally, many timers are equipped with advanced features like adjustable time ranges, multi-function capabilities, and digital displays, allowing operators to fine-tune processes to meet specific operational needs.

In conclusion, timers are vital for optimizing industrial processes, ensuring that operations occur in the correct sequence and at the right time. For companies selling industrial sensors, providing high-performance timers enables customers to achieve greater precision and efficiency in their automation systems. Reliable, durable timers are key to maintaining the smooth operation of machinery and production lines in industrial environments.