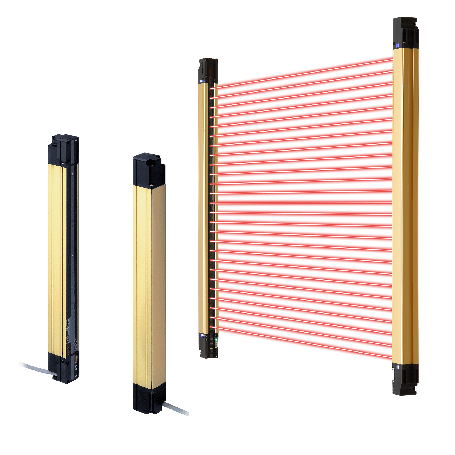

Light Barriers (Light Curtain)

Light barriers and light curtains are essential safety and detection technologies in industrial automation and machine safety. Designed to ensure both operational efficiency and worker safety, these optical sensors create an invisible barrier that detects objects or personnel, triggering immediate responses such as stopping machinery or alerting operators.

Light barriers consist of a transmitter and receiver that emit and detect a beam of light. When the beam is interrupted, the system recognizes the disruption and initiates a predetermined action. This technology is often used for object detection and counting in manufacturing lines or conveyor systems. Light barriers offer precise, non-contact detection, making them ideal for fast-moving or delicate processes. Their reliability and ease of integration make them a common choice in industries where accuracy and speed are critical, such as packaging, electronics, and automotive manufacturing.

Light curtains, on the other hand, are more advanced safety systems designed to protect workers around hazardous machinery. These systems consist of an array of light beams, typically spanning a larger area than light barriers, and are often placed near machine access points. If any of the beams are interrupted, the machine is automatically stopped, preventing accidents. Light curtains are frequently used in areas where traditional physical barriers might slow down operations, such as in robotic work cells, press brakes, or automated assembly lines.

Both light barriers and light curtains offer scalable solutions to meet the specific needs of various industries, from basic detection tasks to complex safety measures. As industrial automation and robotics continue to evolve, these sensor-based technologies are vital for ensuring productivity while maintaining high safety standards, making them indispensable in modern production environments.