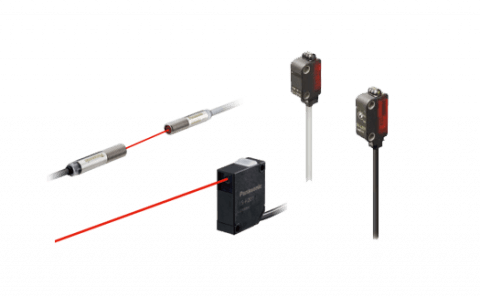

Laser Sensors

Laser sensors are cutting-edge devices used in industrial automation to provide high-precision measurements, distance detection, and object recognition. These sensors utilize laser beams, which offer superior accuracy and the ability to detect even the smallest objects at long distances. Their ability to focus light into a narrow beam ensures pinpoint accuracy, making them ideal for industries requiring meticulous measurement and detection, such as electronics manufacturing, automotive, and robotics.

One of the most notable advantages of laser sensors is their exceptional range and resolution. They can measure distances with micron-level accuracy over both short and long ranges, providing highly reliable performance. This makes laser sensors perfect for applications such as measuring the thickness of materials, detecting small parts on assembly lines, or positioning objects with extreme precision in automated systems. They can also detect objects with a wide variety of shapes, sizes, and surfaces, including highly reflective or transparent materials.

Laser sensors are divided into several types based on their operating principles: time-of-flight (ToF) sensors, triangulation sensors, and displacement sensors. ToF sensors measure the time it takes for a laser beam to reflect back to the sensor, while triangulation sensors calculate the angle of the reflected light to determine distance. Displacement sensors, on the other hand, provide accurate readings of small movements or changes in an object’s position.

Another key benefit of laser sensors is their ability to function in harsh industrial environments. They can operate effectively in challenging conditions such as high temperatures, dust, or moisture, where other sensors might fail. Additionally, laser sensors offer high-speed data collection, which is critical for industries where rapid, real-time monitoring is necessary for maintaining operational efficiency.

In conclusion, laser sensors are a vital component in modern industrial automation. Their unparalleled precision, long-range capabilities, and adaptability to a wide variety of materials and conditions make them essential for ensuring accuracy, efficiency, and safety in automated processes.