With numerous technological advancements, keeping pace with technology has become essential for both individuals and devices. Adapting to these systems is crucial not only for people but also for the equipment and devices being used. Among these evolving needs, distance warning signals are at the forefront. These signals help ensure safety in everyday life.

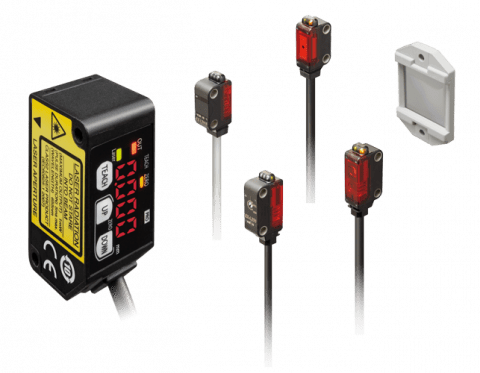

Laser Distance Sensors

Laser distance sensors are designed for non-contact distance measurements. While laser meters are used for measuring ranges up to 10 meters, laser distance sensors are preferred for much greater distances, up to 3,000 meters. These sensors are commonly used for positioning and type classification in machinery and transport equipment.

What is a Laser Distance Sensor?

These sensors operate based on the principle of detecting changes and reductions in light transmission emitted from a laser. This type of measurement is used for highly precise distance measurements. The system functions without disruption thanks to optical beams, ensuring that the processes within the system run smoothly. This allows tasks to be completed more accurately, with higher quality, and in less time. With growing technological advancements and evolving production methods, such systems are becoming increasingly preferred.

Advantages of Laser Distance Sensors

Laser distance sensors provide reliable results even in challenging conditions. Their robust design protects the sensors from dust and splashing water. For outdoor use, models with integrated heating and high protection ratings are particularly recommended.

Their high accuracy makes laser distance sensors ideal for precise distance measurements in industrial environments. Integrated measurement modes ensure reliable results, even on challenging surfaces such as partially reflective, distant, or fast-moving objects. Panasonic laser distance sensors are commonly used in logistics, automation technology, the metal industry, and for production monitoring in distance measurements on various surfaces.

Laser sensors are used in various applications in industrial automation. The diverse range of applications has led to an increased demand for different types of laser sensors. They are used for detection, measurement, or positioning tasks. The common feature of different laser sensors is the advantage provided by the use of laser light. The first advantage is the high light intensity, which allows for extremely precise measurement, positioning, or detection, down to nanometers. Another advantage is the speed of measurement. Due to the use of light as a medium, laser measurement allows for very fast measurements.

Applications of Laser Distance Sensors

- Automation: Level measurement, process control

- Industrial metrology: Non-contact distance, length, and height measurement

- Transportation and logistics, conveyor technology: Distance and height measurement, vehicle detection, collision avoidance

- Steel production and rolling mills: Process control, detection, position measurement, and thickness measurement

- Scanning systems: Fast distance measurement